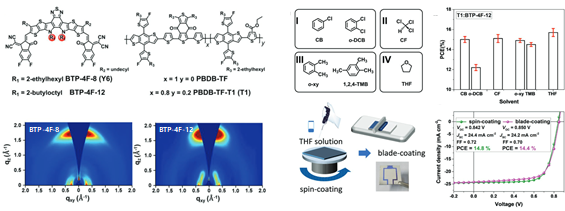

Eco-Compatible Solvent-Processed Organic Photovoltaic Cells with Over 16% Efficiency

Recent advances in nonfullerene acceptors (NFAs) have enabled the rapid increase in power conversion efficiencies (PCEs) of organic photovoltaic (OPV) cells. However, this progress is achieved using highly toxic solvents, which are not suitable for the scalable large‐area processing method, becoming one of the biggest factors hindering the mass production and commercial applications of OPVs. Therefore, it is of great importance to get good eco‐compatible processability when designing efficient OPV materials. Here, to achieve high efficiency and good processability of the NFAs in eco‐compatible solvents, the flexible alkyl chains of the highly efficient NFA BTP‐4F‐8 (also known as Y6) are modified and BTP‐4F‐12 is synthesized. Combining with the polymer donor PBDB‐TF, BTP‐4F‐12 shows the best PCE of 16.4%. Importantly, when the polymer donor PBDB‐TF is replaced by T1 with better solubility, various eco‐compatible solvents can be applied to fabricate OPV cells. Finally, over 14% efficiency is obtained with tetrahydrofuran (THF) as the processing solvent for 1.07 cm2 OPV cells by the blade‐coating method. These results indicate that the simple modification of the side chain can be used to tune the processability of active layer materials and thus make it more applicable for the mass production with environmentally benign solvents.

10.1002/adma.201903441